WORKS案例

我们的作品,他们的故事

Our work, their stories

超低温微风污泥干化设备3d动画

一、项目背景介绍

超低温微风污泥干化设备是可迪尔公司最新研发的一款污泥干化设备,该设备利用最新的处理技术,解决了污泥处理行业中存在的诸多问题。为了更好的向用户展示超低温微风污泥干化设备的特点和优势,可迪尔公司计划将该设备制作成3d动画,利用3d动画的优势全方位展示设备的特点和优势。

北京星尘动画公司作为可迪尔公司的长期合作伙伴,在接到客户的需求后,安排专业技术人员学习了解设备的工作流程和技术要点,详细询问客户的重点需求,并结合星尘公司在动画制作行业的多年经验,为客户设计了贴合客户产品特点并充满动画创意的动画分镜脚本。

在经过充分的沟通修改后,确定最终的动画脚本并开始动画的制作。

二、客户介绍

Calidaddelaire(以下称可迪尔)是由西班牙Herver-9集团创建的品牌,总部位于西班牙马德里,一直专注于为全世界提供先进的空气清洁技术和产品服务,力求尊重自然,回归自然,有效执行节能减排,减少对环境的污染和冲击。

在过去的38年里,Herver-9集团不断推陈出新,使得其品牌长久不衰,迄今,已形成企业独有的核心竞争优势,其产品广泛应用于欧美的工业厂房等处。随着中国对环境保护要求的提高,Herver-9集团看好中国市场,2014年进入中国,并在中国开展了研发、生产、销售和售后服务等业务。可迪尔愿意把其专业的产品和技术带入中国,给中国带来最专业的工业废气解决方案。

三、超低温微风污泥干化设备3D动画成片

四、超低温微风污泥干化设备3D动画详细介绍

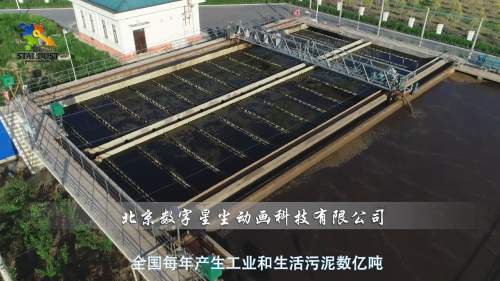

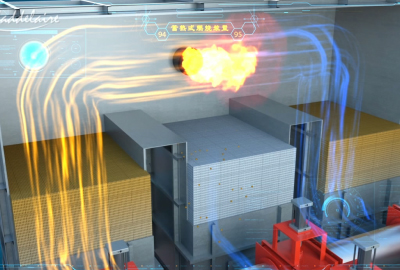

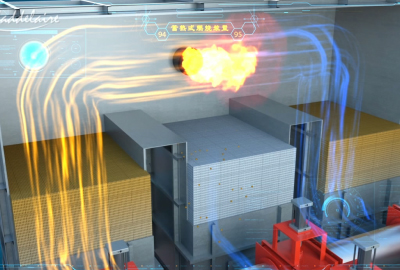

1、根据最终确定动画脚本,动画的开头首先展示的是可迪尔公司的蓝色LOGO,下面是动画的名称,然后就是一个污泥处理行业的背景介绍,背景介绍不适合使用3d动画场景,使用实拍的视频更有说服力,在经过分析和比较后,动画师果断采用实拍视频的形式来展示行业背景。视频内容展示的是污泥处理厂在进行污泥干化处理的场景和流程,以此引出污泥处理行业存在的问题。

全国每年产生工业和生活污泥数亿吨,大部分污泥含水率高、脱水难、产恶臭、易造成二次污染。可迪尔针对污泥减量与资源化,研发了第二代超低温微风污泥干化设备,解决传统设备粉尘大、臭气外溢、设备腐蚀、工作温度高和成本高等难题,为污泥除水减量提供最佳解决方案。

Hundreds of millions of sludge are generated every year from industries and daily life in China, and most sludge has a high moisture content, smell, and unmanageable in dehydration, and cause secondary pollution. Calidaddelaire aims at sludge reduction and recycling, and develops the 2nd generation ultralow temperature breathing drying equipment for sludge processing. Previous difficulties of large dusts, smell, device corrosion, overheating and high cost are all solved. Calidaddelaire provides the best solutions to sludge reduction!

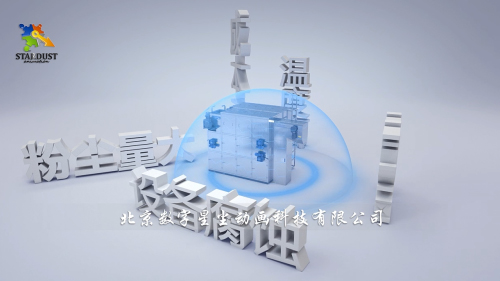

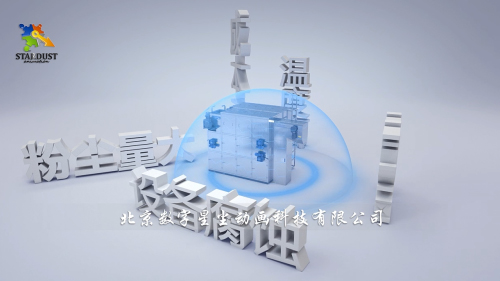

2、展示完污泥行业背景后,进入正式的3d动画展示画面,开场的3d动画是几个白色的方块拉出一个5边型的洞口,洞口慢慢变大,洞的里面缓缓升出一个金属外壳的设备,这个设备就是需要展示的超低温微风污泥干化设备,采用全数字化建模技术创建的产品3d模型,并配以金属材质,使设备高端大气。

污泥干化设备在360度旋转,从上面点下几个立体的大字,文字的内容是:粉尘量大,设备腐蚀,臭气外溢,温度高,成本高,这些都是困扰污泥干化行业的难题,这时3d动画表现的意思是这些难题像几座大山一样压着,这时设备的外面出现一层蓝色的保护膜,把这些大山都隔离在外面。主旨意思是这些大山一样的难题并不能压垮这一款污泥干化设备。从而引出该设备的技术优势。

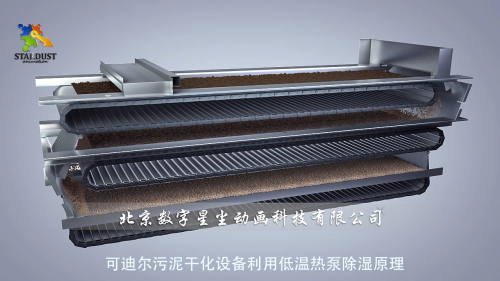

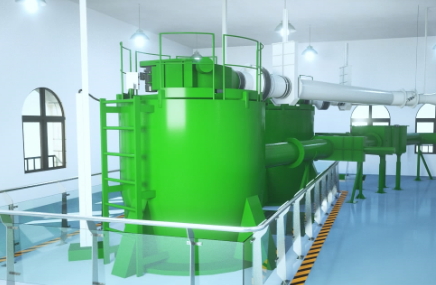

3、动画的画面由设备的外观切换到设备的内部,污泥干化设备的内部已经开始工作,3条传送带在不停的转着,上面的污泥颗粒也在不停的运动,观看者通过这个动画画面可以了解污泥干化除湿的原理。同过这样的展示,不仅行业内的专业人员能够看懂,我们普通人也能看明白他的工作原理。动画的背景采用淡灰色背景,简单大气。

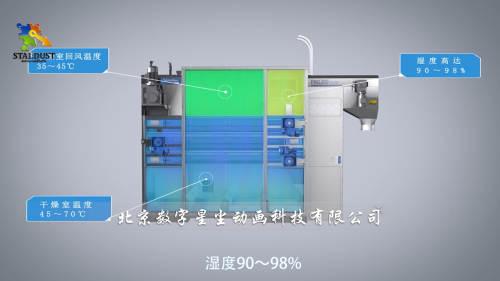

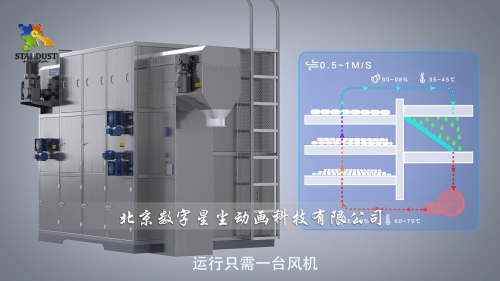

可迪尔污泥干化设备利用低温热泵除湿原理,采用独立风道、湿度梯度抽湿干燥技术,干燥室温度仅45~70℃,干燥室回风温度35~45℃,湿度90~98%,回风口达到露点,可快速冷凝排水。系统为闭环设计,运行只需一台风机,有效防止臭气外溢,并配置热回收装置,节约10-20%的能耗。干燥室内配有吸收粉尘与酸、碱、盐的装置,确保设备不受腐蚀,真正实现了节能和低粉尘的特点。

Calidaddelaire sludge-drying equipment works through dehumidification by means of the low-temperature heating pump. It adopts independent air flue and gradient dehumidification technology. The drying room can be kept at 45~70℃ with the return air at 35~45℃ and humidity at 90~98%. air at the air flue port can condense and be discharged at dew point. Close-loop design of the system only requires one draught fan to prevent the smell; heat recycling device is equipped for saving 10-20% energy. Vacuum devices are equipped within the drying room to clean the powders, acid, alkali, and salt to prevent from corrosion for the real energy-saving and low dust.

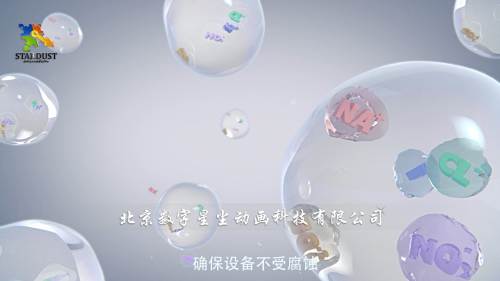

4、动画在展示设备工作原理的时候,为了更形象的展示运行原理,动画师还设计了一个二维的原理动画,将整个流程通过二维图形展示出来。设备在处理污泥时,污泥会发生化学反应,化学反应都是微观级别的,我们肉眼根本看不到。那怎样才能更好的展示微观的分子反应过程呢?为此动画师设计了一个微观分子反应展示动画镜头。

将一些水分子等使用化学代号来表示,不同的颜色代表不同的分子。这样我们就能看清楚微观级别的工作状态,提升了设备的特点和优势,也提升了设备的价值和作用。

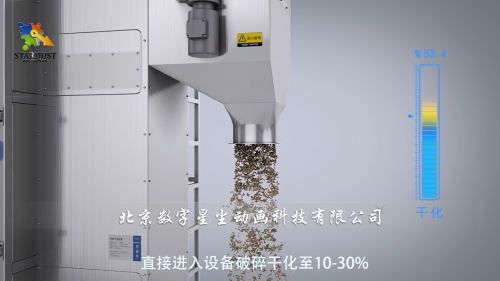

本设备广泛适用于含水率40-90%的污泥处理,确保压滤机发挥最高的除水效益。湿泥无须压条,直接进入设备破碎干化至10-30%,广泛应用于市政和工业污泥的干化减量。

The equipment is widely used to process the sludge with a moisture content of 40-90% for a maximum effect by the filter press. Wet sludge can be directly crushed and dried to 10-30%. The device is widely applied to sludge reduction for municipal works and industries.

可迪尔将秉承感恩·卓越的发展理念,坚持“以效果为导向,以品质为前提,以技术为基础”,稳扎稳打,服务于污泥干化行业。

Calidaddelaire sticks to the development value of gratitude and excellence, and centers on “efficiency-orientated, quality-based, and technology-underpinned” to serve the sludge drying industry sincerely.

动画的结尾引出可迪尔公司的发展理念,为整个动画画上一个完美的句号。

五、总结

污泥处理行业关系到环境的污染和保护,处理不当就可能对我们的生活环境造成损害,从而影响我们的健康,所以国家一直以来大力支持环保行业的建设,各类环保公司也在各自的行业中发挥着积极的作用。我们通过制作超低温微风污泥干化设备3d动画,学习到了很多关于污泥干化方面的知识,并对环保行业的发展有了一个全新的认识,为我们以后制作环保设备行业3d动画打下了坚实的基础。

超低温微风污泥干化设备3d动画项目的顺利完工,标志这我们又为客户提供了一次满意的动画制作服务,动画制作不仅是需要制作精美的动画作品,更重要的是在合作的过程中让客户感受到公司的专业性和周到服务,这样才能为以后的长期合作打下基础。北京星尘动画作为一家专业的动画制作公司一直努力在动画制作行业里深耕细作,努力为用户提供更精美的动画作品和满意服务。

相关案例

-

智能电暖器是江阴欧伟士公司最新设计的一款智...

-

天津生态城生活垃圾气力自动收集系统三维动画...

-

疏水性沸石浓缩系统是可迪尔空气技术(北京)...

-

工业机器视觉系统是北京兆维集团自主研发的新...